Leading the Development of Small and Medium Size Machinery Industry

in Gyeonggi, Incheon

Gyeonggi Incheon

Machinery Industrial Cooperative

Leading the Development of Small and Medium Size Machinery Industry

in Gyeonggi, Incheon

Gyeonggi Incheon

Machinery Industrial Cooperative

KOREA ENVI-TECH CO., LTD.

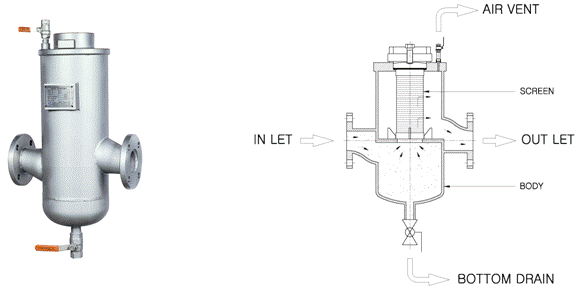

Water-processing Pump

Water-processing Pump(KMS)

.png)

.png)

DongiI Canvas Engineering Co. LTD.

Water-processing Pump

Water-processing Pump(Screw dehydrator)

GIMICO

Gyeonggi

Incheon

Machinery

Industrial

Cooperative

Introduce

Movie

Leading the Development of Small and

Medium Size Machinery Industry

in Gyeonggi, Incheon, Korea